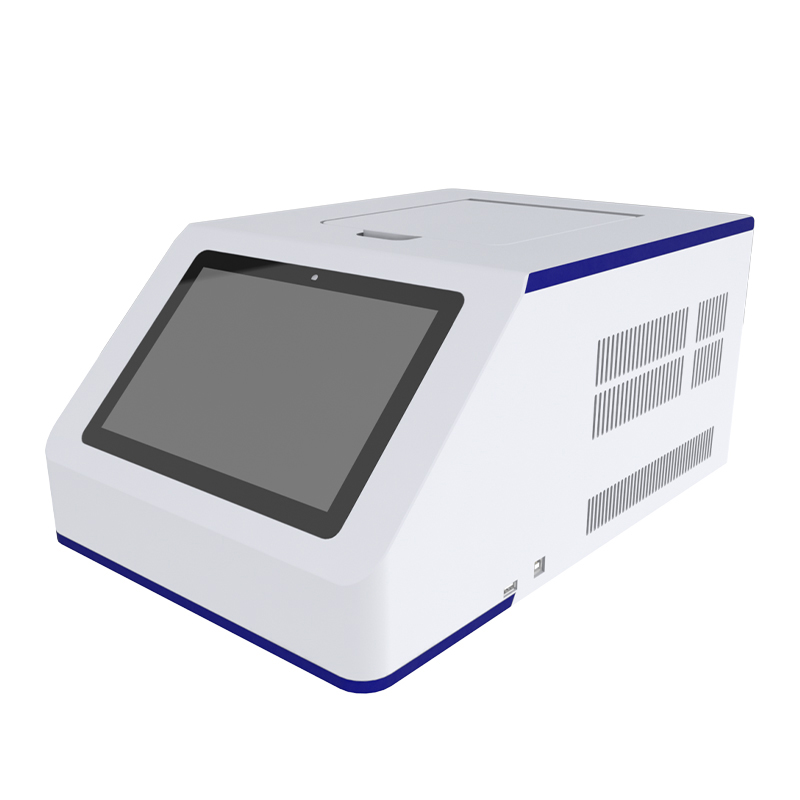

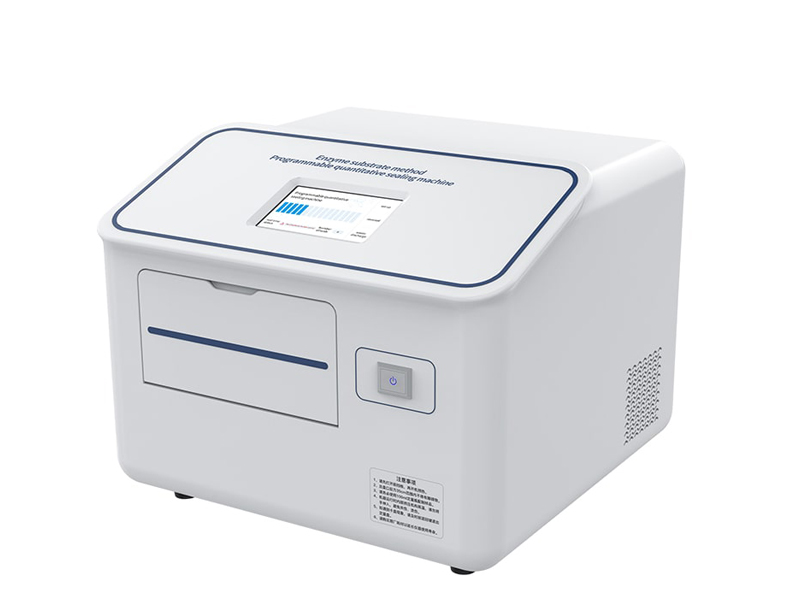

As the core equipment of enzyme substrate microbial detection system, Programmable Sealer is far from a simple sealing tool. It is a key technological breakthrough for achieving rapid, standardized, and on-site monitoring of modern water quality safety. I have been deeply involved in this field for over ten years, and this article will delve into its technical connotation and application value.

Why is the programmable quantitative sealing machine the cornerstone of the microbial detection revolution?

Traditional microbial detection methods (multi tube fermentation method, membrane filtration method) have significant bottlenecks:

Long and time-consuming: The cultivation and result interpretation process takes 48-72 hours, which delays emergency response.

Complicated operation: large amount of glassware cleaning, preparation of culture medium, high labor cost.

Strong environmental dependence: requires a professional sterile laboratory, difficult to operate on site.

Subjective error: The interpretation of results relies on personnel experience and is prone to false positives/false negatives.

The core value of the program-controlled quantitative sealing machine lies in its perfect integration of the technological advantages of the "enzyme substrate method", and through precise automation of the sealing process, it transforms theoretical advantages into stable and reliable detection results.

Core principle: Intelligent temperature control sealing and quantitative design

Precision heat sealing core:

The device is equipped with a high-precision heating roller system, with a temperature control accuracy of ± 0.5 ℃.

Based on the preset program, the optical transparent film covering the top of the dedicated 51 well/97 well quantitative disk (containing enzyme substrate culture medium) is subjected to instantaneous and uniform hot melt sealing.

Core requirement: Form a completely sterile and bubble free sealed chamber to ensure that water samples and reagents react in independent wells and prevent cross contamination.

Quantification of MPN statistical models:

The design of the 51 hole/97 hole quantitative disk is based on the principle of maximum possible number (MPN) statistics.

Each cavity is equivalent to an independent micro culture unit. The number of positive wells (color/fluorescence) is statistically correlated with the concentration of target bacteria in the sample, and quantitative results (MPN/100mL) can be directly obtained through a dedicated MPN table or software.

An irreplaceable technological advantage

Fast and efficient, seize emergency opportunities:

The sealing process only takes a few seconds, and with the enzyme substrate method, the total detection time is shortened to 24 hours, providing a critical time window for pollution warning and emergency water safety incident disposal.

Accurate and reliable, authoritative data:

Programmed temperature control sealing ensures highly consistent sealing between batches and holes, eliminating human operational differences.

The enzyme substrate method has strong specificity and a significantly lower false positive rate compared to traditional methods, and the results comply with national standards (GB/T 5750.12-2023, HJ 1001-2018, etc.).

Minimalist operation, freeing up manpower:

The "one click sealing" design allows operators to get started with simple training. Save a lot of tedious preparation of culture media and sterilization of containers.

Extremely adaptable to the environment:

The device is designed for miniaturization and portability, with built-in batteries or compatible car power sources. It can operate in outdoor, emergency vehicles, simple laboratories, and other scenarios, breaking through laboratory limitations and achieving the goal of "testing wherever the sample is".

Significant cost-effectiveness:

Reduce laboratory space and investment in large sterilization equipment; Significantly reduce the cost of manpower and consumables (such as test tubes, straws, culture media); Improving throughput, the daily sample processing capacity of a single machine far exceeds traditional methods.

Widely covered water quality safety application areas

The enzyme substrate method solution supported by the programmable quantitative sealing machine has been deeply applied in:

Drinking water safety: Monitoring of water supply plants (source water, process water, finished water, pipe network end water), bottled water, and secondary water supply.

Environmental water monitoring: Routine monitoring of surface water (rivers, lakes, reservoirs), beaches, landscape water, and groundwater at national/provincial control points.

Sewage treatment supervision: standard testing of inflow and outflow of sewage plants (CJ/T51-2018), safety assessment of reclaimed water reuse.

Emergency response: Rapid assessment of water quality after sudden water pollution incidents (such as pipeline ruptures, floods), and natural disasters.

Food and production water: Quality control of water used in beverage factories, food processing plants, animal husbandry, and medical/pharmaceutical institutions.

Research and third-party testing: Efficient testing solutions for universities, research institutions, and environmental/food testing laboratories.

The program-controlled quantitative sealing machine is not a simple accessory equipment, it is the core driving force that promotes the efficient, accurate, portable, and intelligent era of water quality microbiological detection. It is based on intelligent temperature control precision sealing technology, perfectly adapted to the advanced principle of enzyme substrate method, and completely solves many constraints of traditional methods. In today's increasingly emphasized emphasis on water quality safety and emergency response, mastering and utilizing this core technology has become an inevitable choice for water companies, environmental protection departments, testing institutions, and water related industrial enterprises to enhance monitoring capabilities, ensure public safety, and optimize operational efficiency. As an engineer, I witness and continue to drive the outstanding contribution of this technology in safeguarding the source of life.

Article address:https://www.molecularbio.cn/news/32.html