Detection principle and significance

Escherichia coli in water is a key biological indicator for assessing fecal contamination and potential pathogenic risks in water bodies. This scheme adopts the enzyme substrate method (according to the national standard GB/T 5750.12-2023), which generates fluorescent signals through E. coli specific enzymatic hydrolysis reaction, and combines with Hengmei intelligent equipment to achieve rapid and accurate quantitative detection. The whole process can be completed within 24 hours.

Core instrument configuration

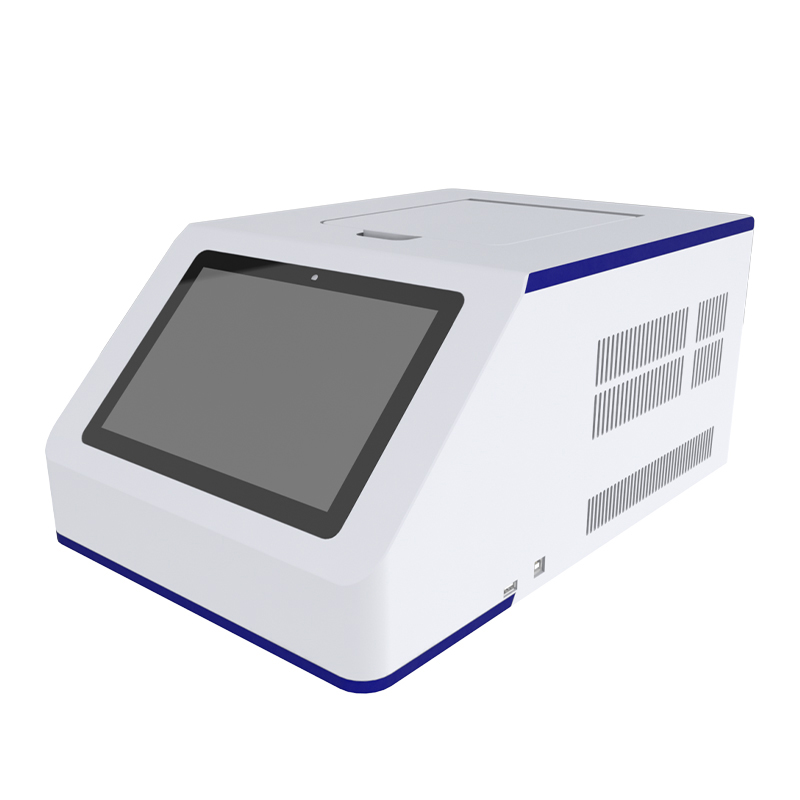

1、Hengmei HM-W80 Microbial Rapid Detector

Function: Fully automatic interpretation of fluorescence reactions in quantitative detection disks (51/97 wells)

Characteristic:

Optical recognition system automatically distinguishes positive/negative holes

Built in MPN algorithm directly generates colony concentration (MPN/100mL)

7-inch touch screen real-time display detection process

Data storage and USB export function

2、Hengmei Programmable Quantitative Sealing Machine

Function: Aseptic sealed quantitative detection disk

Characteristic:

Programmed temperature control (180 ± 5 ℃) and pressing time (3 seconds)

Anti scald safety design and automatic standby function

Compatible with 51/97 hole standard disks

Standardized testing process

Step 1: Water sample collection and pretreatment

Collect 500mL of water sample to be tested using sterile sampling bottles

If the water sample contains residual chlorine, add sodium thiosulfate for neutralization (add 10% solution at a rate of 0.1mL/500mL)

The turbid water sample needs to be pre treated with a filter membrane (0.45 μ m)

Step 2: Reagent addition and mixing

Add 1 bag of Escherichia coli enzyme substrate reagent (including ONPG and MUG) to every 100mL of water sample

Manually oscillate for 30 seconds or mix with a vortex mixer until the reagent is completely dissolved

Step 3: Program controlled quantitative sample sealing

Inject the water sample into the quantitative detection tray using a sterile pipette

Preheat the programmable sealing machine until the green light comes on

Place the detection disk into the sealing area and automatically complete the hot press sealing

Step 4: Constant temperature cultivation

Place the sealed detection disk into a 36 ± 1 ℃ incubator

Cultivate in the dark for 24 hours

Step 5: HM-W80 Automated Interpretation

Place the cultivated detection tray into the instrument tray

Start the scanning program:

365nm UV light source excitation fluorescence (MUG hydrolysis product)

Optical sensor automatically recognizes positive holes (with yellow fluorescence)

The instrument automatically calculates and displays the MPN value

Print inspection report or export electronic data

Key points of quality control

Blank control: Each batch of testing must include a sterile water negative control

Positive control: Add standard Escherichia coli strains (such as ATCC 25922) to verify the effectiveness of the reagent

Environmental monitoring: Daily temperature recording deviation of incubator ≤ ± 0.5 ℃

Equipment calibration: HM-W80 conducts monthly optical module calibration

Core advantages of the plan

1、Efficiency improvement:

Sealing machine with a sealing speed of 3 seconds per disc to avoid manual errors

HM-W80 can complete single disk reading within 90 seconds

2、Accurate compliance:

Built in national standard MPN calculation model to avoid manual table lookup errors

The data traceability system meets the requirements of CMA/CNAS certification

3、Cost optimization:

The cost of consumables for a single test is lower than that of traditional multi tube fermentation methods

Reduce manual interpretation time by more than 50%

This solution has been successfully applied to water treatment plants, sewage treatment plants, and third-party testing institutions, achieving standardized management of the entire process from "sampling analysis reporting", providing reliable technical support for drinking water safety and environmental monitoring.

Article address:https://www.molecularbio.cn/solu/24.html