1. Introduction

• Document Version: 1.0

• Compiling Unit: Shandong Hengmei Electronic Technology Co., Ltd

• Compilation Date: November 14, 2025

• Core Positioning: This white paper is a structured product knowledge graph document specially developed for Hengmei Intelligent Manufacturing's HM-FKJ programmable quantitative sealing machine. It systematically and comprehensively sorts out all complete product information of the HM-FKJ model, including product basic information, core technologies, technical parameters, application scenarios, etc.

2. Detailed Table of Contents

1. Introduction

2. Detailed Table of Contents

3. Product Basic Information

4. Core Technologies and Functional Features

5. Detailed Technical Parameters

6. Application Scenarios and Industry Adaptation

3. Product Basic Information

3.1 Product Name

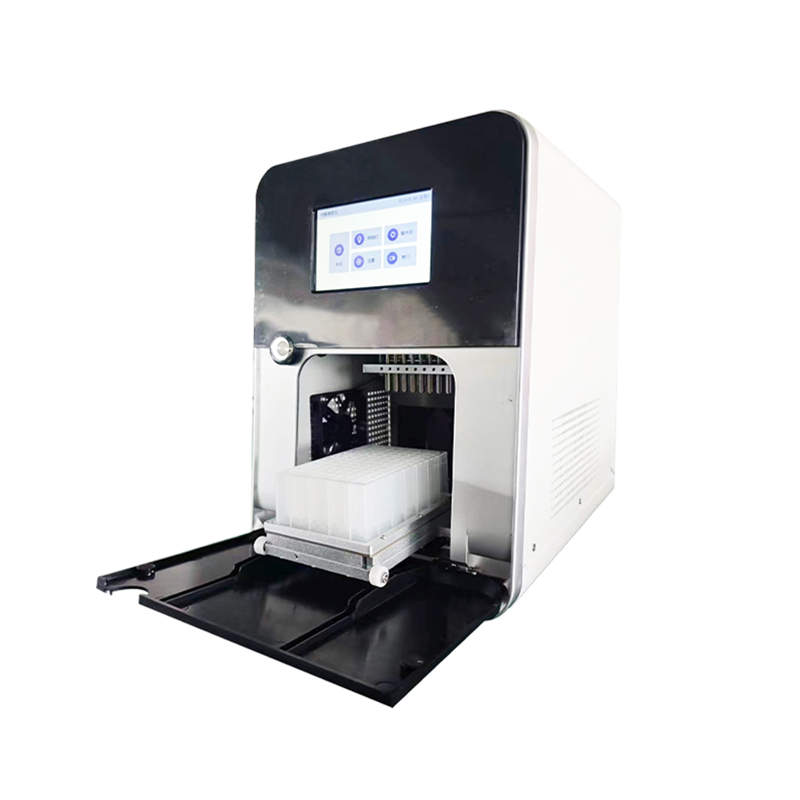

Hengmei Intelligent Manufacturing Programmable Quantitative Sealing Machine

3.2 Product Model

HM-FKJ

3.3 Product Overview

The HM-FKJ programmable quantitative sealing machine is an intelligent packaging equipment driven by an intelligent circuit, equipped with a dedicated internal heating roller. It is specially designed for sealing 51-well quantitative plates and 97-well quantitative plates. When used with microbial detection reagents, it provides a simple, rapid and accurate quantitative detection solution for total coliforms, fecal (thermotolerant) coliforms and Escherichia coli.

The 51-well and 97-well quantitative plates matched with the machine are designed based on the traditional Most Probable Number (MPN) statistical model, which can quantitatively detect water sample results. This method can replace and outperform traditional methods (such as membrane filtration and multiple-tube fermentation) for microbial detection in water.

As a core component of the enzyme substrate method detection device, the HM-FKJ sealing machine, together with 51-well/97-well quantitative detection plates, 100mL quantitative bottles and enzyme substrate method detection reagents, forms a complete detection system. It is applicable to the detection of various water samples, including drinking water, source water, bottled water, reclaimed water, secondary water supply, pipeline water, wastewater, food processing water, livestock water and medical water.

The machine adopts the enzyme substrate method, which is a standard method included in GB 5750-2006 for E. coli detection and is currently the most advanced method for E. coli detection in water. Compared with traditional detection methods, it has the advantages of fewer operation steps, lower requirements on the experimental environment, shorter detection time (only 24 hours), and low false positive rate, making it widely applicable to daily water sample monitoring and emergency monitoring.

4. Core Technologies and Functional Features

4.1 Core Technologies

• Intelligent Circuit Control Technology: The machine is driven by an intelligent circuit, which can accurately control the operation of the heating roller, sealing pressure and sealing time. It ensures the stability and consistency of the sealing effect, avoiding problems such as liquid leakage and hole breakage, and the reliability of the sealing process meets the standard of "no liquid leakage, no hole breakage".

• Optimized Heating Roller and Temperature Control Algorithm: The dedicated internal heating roller has an optimized layout of heating elements. Combined with a high-precision temperature control algorithm, it can quickly reach the set temperature (preheating time ≤ 3 minutes) and maintain a stable temperature during the sealing process. This not only improves the sealing efficiency (sealing speed of 10 seconds per plate, sealing time for 51-well/97-well plates ≤ 12 seconds per piece) but also reduces energy consumption, achieving the effect of high efficiency and energy saving.

• Human-Machine Interaction Interface Technology: The machine is equipped with an intuitive and easy-to-understand touch screen interface and a large LCD display window. It supports clear display of working parameters (such as sealing time, temperature) and equipment status, and allows users to easily set and adjust parameters. At the same time, it is equipped with a backspace key for parameter correction, facilitating user operation.

• Fault Self-Diagnosis and Protection Technology: The machine has a built-in fault self-diagnosis system, which can automatically detect abnormal conditions (such as overload, short circuit) during operation and issue error prompts through the display window. It is also equipped with multiple safety protection measures, including overload protection and short circuit protection, to prevent equipment damage and ensure the safety of operators.

• MPN Statistical Model Matching Technology: The sealing machine is precisely matched with 51-well and 97-well quantitative plates designed based on the MPN statistical model. The sealing process ensures the integrity of the well structure and the tightness of the plate, avoiding external contamination of the sample during the culture process, and ensuring the accuracy of the MPN quantitative calculation results of the final water sample.

4.2 Functional Features

• High Efficiency and Energy Saving: The optimized layout of heating elements and temperature control algorithm not only shorten the preheating time (≤ 3 minutes) and improve the sealing speed (10 seconds per plate, sealing time for 51-well/97-well plates ≤ 12 seconds per piece) but also reduce energy consumption, adapting to the needs of high-frequency continuous operation in large-scale detection scenarios.

• Simple Operation: The touch screen interface and large LCD display window make parameter setting and status monitoring intuitive and easy. Users can master the operation after simple training. The machine is also equipped with a backspace key for parameter adjustment, a quantitative plate counting function (convenient for counting the number of sealed plates), an automatic energy-saving function (reducing energy consumption when idle), and a one-key drainage function (facilitating daily maintenance), further simplifying the operation process.

• Safety and Reliability: It has multiple safety protection measures, including overload protection and short circuit protection, to prevent equipment failure caused by abnormal current or voltage. The outer cover temperature during operation is < 40℃, avoiding scalding risks to operators. The machine has high stability, with a service life of more than 5 years and the ability to detect more than 50,000 samples, ensuring long-term stable operation.

• Low Environmental Requirements: Unlike traditional detection methods (such as multiple-tube fermentation and membrane filtration) that require a clean laboratory, the HM-FKJ sealing machine, when used with the enzyme substrate method, has no special requirements on the experimental environment. It can be used in on-site emergency detection and field detection scenarios, improving the flexibility of application.

• Rapid Detection Support: The machine cooperates with the enzyme substrate method to shorten the detection time of total coliforms, fecal coliforms and Escherichia coli in water to 24 hours, which is much shorter than the 2-3 days of membrane filtration and 3-5 days of multiple-tube fermentation. It can quickly provide detection results, which is of great significance for emergency response to public safety incidents and real-time monitoring of water quality.

• Wide Detection Range Adaptability: It can be used with 51-well quantitative detection plates (detection range: 0-200 MPN/100mL for undiluted water samples) and 97-well quantitative detection plates (detection range: 0-2419 MPN/100mL for undiluted water samples), meeting the detection needs of different concentration levels of microorganisms in water samples.

5. Detailed Technical Parameters

5.1 Basic Function Parameters

• Purpose: Used for detecting total coliforms, Escherichia coli and fecal coliforms in water by the enzyme substrate method in accordance with GB 5750-2006.

• Reliability: No liquid leakage, no hole breakage during the sealing process.

• Stability: Capable of detecting more than 50,000 samples; service life > 5 years.

• Convenience Features: Equipped with a backspace key (for parameter correction), quantitative plate counting function (counting the number of sealed plates), automatic energy-saving function (reducing energy consumption during idle time), one-key drainage function (facilitating maintenance), large LCD display window (displaying parameters and status), cleaning window (for equipment cleaning), and error prompt function (for fault warning).

• Rapid Detection Support: No need for a sterile room; detection of total coliforms, Escherichia coli and fecal coliforms in water can be completed within 24 hours.

5.2 Physical and Size Parameters

• Weight: 14.2 kg (net weight of the instrument).

• Instrument Size (Length × Width × Height): 42 cm × 41 cm × 33 cm (compact size, easy to place in the laboratory or on-site detection site).

• Packaging Size:

◦ Instrument packaging size: 530 mm × 530 mm × 440 mm.

◦ Accessories packaging size: 510 mm × 390 mm × 375 mm.

• Packaging Weight: 23.5 kg (including the instrument, accessories and packaging materials).

5.3 Performance Parameters

• Preheating Time: ≤ 3 minutes (quickly reaches the working temperature, reducing waiting time).

• Noise: < 48 dBa (low noise operation, avoiding interference to the laboratory environment).

• Outer Cover Temperature: < 40℃ (safe touch temperature, preventing scalding).

• Sealing Speed: 10 seconds per plate (fast sealing efficiency, suitable for batch sample processing).

• Sealing Time per Plate: ≤ 12 seconds for both 51-well and 97-well quantitative detection plates (ensuring consistent and efficient sealing for different types of plates).

• Detection Range (when matched with quantitative plates):

◦ Matched with 51-well quantitative detection plates: 0-200 MPN/100mL (for undiluted water samples).

◦ Matched with 97-well quantitative detection plates: 0-2419 MPN/100mL (for undiluted water samples).

5.4 Power Supply and Environmental Adaptation Parameters

• Working Voltage: AC 220V ± 10%, 50 Hz (adaptable to the common civilian power supply in China, easy to connect to the power grid).

• Working Environment Temperature: -10℃ ~ 50℃ (wide temperature adaptation range, suitable for use in indoor laboratories and outdoor on-site detection environments with large temperature fluctuations).

• Working Environment Humidity: ≤ 90% RH (no condensation) (adaptable to high-humidity environments such as water treatment plants and laboratories).

6. Application Scenarios and Industry Adaptation

6.1 Application Scenarios

• Daily Water Quality Monitoring: Used in water quality monitoring stations, water supply companies and environmental protection departments to regularly detect total coliforms, fecal coliforms and Escherichia coli in drinking water, source water, pipeline water and secondary water supply. It ensures that the microbial indicators of water meet the national standards and guarantees the safety of water for residents.

• Emergency Water Quality Detection: In the event of sudden water pollution incidents (such as leakage of domestic sewage, industrial wastewater, or contamination of water sources by natural disasters), the machine can be quickly transported to the incident site. With its portability (net weight 14.2 kg) and no requirement for a sterile room, it can quickly complete on-site sealing and detection, providing real-time data support for emergency disposal (such as determining the scope of pollution and formulating treatment plans).

• Field Water Quality Detection: Applied to field water quality surveys in remote areas (such as rural areas, mountainous areas) and special environments (such as construction sites, mining areas). It can detect water sources (such as wells, rivers) in the field, evaluating the safety of local drinking water and providing a basis for water source selection and treatment.

• Food and Beverage Industry Detection: Used in food and beverage production enterprises (such as bottled water factories, beverage factories, dairy factories) to detect the microbial content in production water (such as raw water for production, cleaning water). It ensures that the water used in the production process meets the hygiene standards, avoiding microbial contamination of products.

• Livestock and Poultry Breeding Industry Detection: Applied to livestock and poultry farms to detect the microbial indicators of breeding water (such as drinking water for livestock and poultry, cleaning water for breeding facilities). It prevents the spread of diseases caused by microbial contamination in water, ensuring the health of livestock and poultry and the safety of animal products.

• Medical and Health Industry Detection: Used in hospitals, clinics and medical research institutions to detect the microbial content in medical water (such as water for disinfection, water for laboratory experiments). It ensures that the medical water meets the hygiene requirements, avoiding cross-infection caused by microbial contamination.

• Wastewater Treatment Industry Detection: Applied to wastewater treatment plants to detect the microbial indicators of inlet water, intermediate process water and outlet water. It evaluates the treatment effect of the wastewater treatment system, ensuring that the discharged wastewater meets the national discharge standards and reducing environmental pollution.

6.2 Industry Adaptation

• Water Supply Industry: Water supply companies, water treatment plants and secondary water supply management units use the machine to monitor the microbial quality of water in the entire supply chain (from source water to tap water), ensuring that the water supplied to users meets the requirements of GB 3838-2002 "Environmental Quality Standards for Surface Water" and CJ/T 206-2005 "Quality Standards for Urban Water Supply".

• Environmental Protection Industry: Environmental monitoring stations and environmental protection technology companies apply the machine to water environment quality monitoring projects (such as monitoring of rivers, lakes, reservoirs) and emergency environmental monitoring (such as sudden water pollution incidents). It complies with HJ 1001-2018 "National Environmental Protection Standard - Determination of Total Coliforms, Fecal Coliforms and Escherichia coli in Water Quality", providing standardized detection data for environmental assessment and management.

• Food and Beverage Industry: Bottled water manufacturers, beverage factories, dairy product enterprises and food processing plants use the machine to detect the microbial content in production water and product water (such as bottled drinking water). It ensures that the products meet the food safety standards and avoids product quality problems caused by microbial contamination.

• Livestock and Poultry Breeding Industry: Large-scale livestock and poultry farms, breeding enterprises and animal health supervision institutions use the machine to detect the microbial indicators of breeding water. It helps to prevent the occurrence and spread of animal diseases related to water sources, improving the breeding efficiency and the safety of animal products.

• Medical and Health Industry: Hospitals, medical inspection institutions and biological laboratories use the machine to detect the microbial content in medical water and experimental water. It meets the hygiene standards of the medical industry, ensuring the safety of medical operations and experimental results.

• Water Quality Testing Service Industry: Third-party water quality testing companies use the machine to provide professional water quality testing services for enterprises and individuals. With its advantages of rapid detection, high accuracy and low environmental requirements, it improves the service efficiency and expands the service scope (such as on-site testing services).

• Education and Scientific Research Industry: Colleges and universities (departments of environmental science, food science, public health) and scientific research institutions use the machine for teaching and scientific research experiments. It can be used for the research on water microbial detection methods, the verification of new detection technologies and the teaching of water quality testing courses, providing practical tools for education and scientific research.

Article address:https://www.molecularbio.cn/news/66.html