Surface cleanliness is an important indicator for measuring hygiene quality, directly affecting product quality and production safety. Traditional microbial detection methods require complex cultivation processes, taking as long as 24-48 hours, which cannot meet the demand for real-time hygiene monitoring in modern production. The surface cleanliness tester, based on ATP bioluminescence technology, achieves rapid and accurate assessment of surface cleanliness, providing an efficient hygiene monitoring solution for various industries.

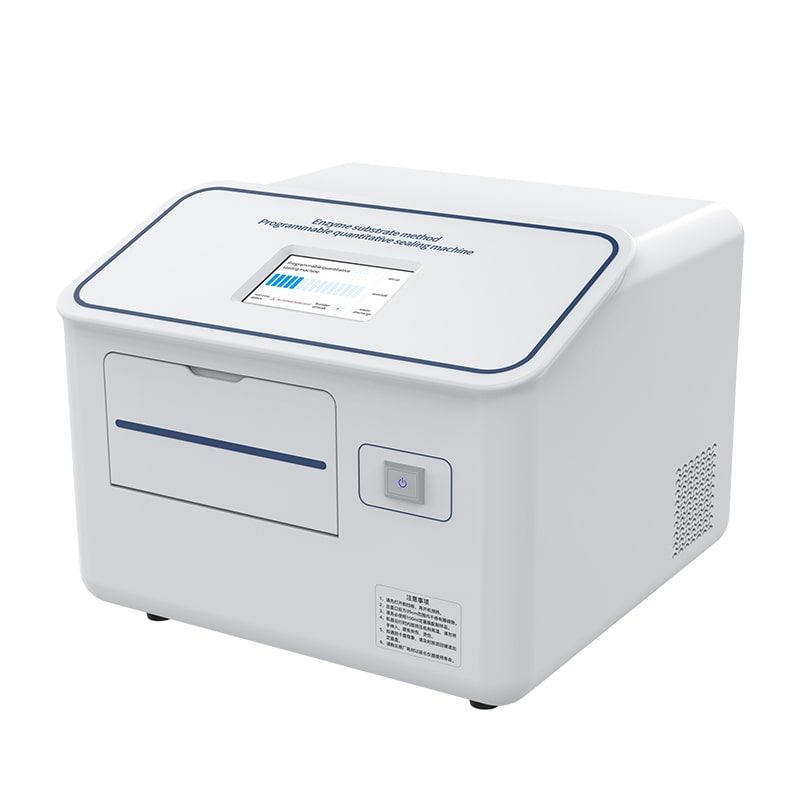

Equipment Overview

The surface cleanliness tester is a rapid detection device that uses biochemical luminescence principles. The instrument evaluates surface cleanliness by detecting adenosine triphosphate (ATP) content. ATP is an energy carrier in all living cells, and its content accurately reflects the degree of microbial contamination. The instrument is equipped with a 3.5-inch high-precision graphic touch screen and uses a 32-bit high-speed data processing chip. With a detection accuracy of up to 1×10⁻¹⁸ mol, it can complete detection in 15 seconds, greatly improving hygiene monitoring efficiency.

Working Principle

1. ATP Bioluminescence Technology

Based on the firefly luminescence principle, the "luciferase-luciferin system" is used to detect ATP content. The reagents contained in the ATP swab can lyse cell membranes, releasing intracellular ATP. ATP reacts with specific enzymes in the reagent to produce photons. The instrument quantitatively analyzes ATP content by detecting the luminescence value (RLU).

2. Detection Process

Sampling → Activating the swab → Inserting into the instrument → Detection reading → Result analysis. The entire process takes only 15 seconds to obtain quantitative data on surface cleanliness. The number of microorganisms is proportional to the luminescence value, and the RLU value provides an intuitive understanding of the surface's hygiene status.

Technical Advantages

Rapid and Efficient: Traditional microbial cultivation takes 18-24 hours, while the surface cleanliness tester provides results in just 15 seconds, significantly improving detection efficiency and making it suitable for on-site rapid screening.

High Sensitivity: With a detection accuracy of 1×10⁻¹⁸ mol, it can detect trace amounts of microbial contamination, ensuring the accuracy of hygiene monitoring.

User-Friendly Operation: The touchscreen operation and intuitive interface allow general staff to operate independently after minimal training. The swab sleeve features a plug-and-play design, which can be regularly cleaned to extend its service life.

Smart Functions: Customizable upper and lower limit values allow automatic pass/fail judgments. A built-in self-calibrating light source ensures detection accuracy. Data export is supported via a miniUSB interface, enabling detection results to be uploaded to a computer for analysis.

Application Fields

The surface cleanliness tester is widely used in the following fields:

Food Processing: Production line hygiene monitoring, HACCP system verification

Medical and Epidemic Prevention: Medical device surface cleanliness detection, hospital infection control

Pharmaceutical Industry: Clean area environmental monitoring, GMP compliance verification

Food Service: Tableware cleanliness inspection, kitchen hygiene management

Water Quality Monitoring: Drinking water hygiene and safety inspection

Public Health: Hygiene supervision in public places such as schools and hotels

Industrial Production: Cleanroom monitoring in industries such as semiconductors and electronics

Industry Pain Points and Solutions

Low Detection Efficiency: Traditional microbial detection methods are time-consuming and cannot meet real-time monitoring needs.

Solution: 15-second rapid detection enables on-site instant monitoring and timely identification of hygiene issues.

High Professional Skill Requirements: Traditional methods require specialized technical personnel to operate.

Solution: Intelligent design and user-friendly operation allow general staff to operate after training.

Inconvenient Data Management: Manual recording is error-prone and makes trend analysis difficult.

Solution: Data export and analysis support facilitate hygiene quality trend monitoring.

Cost Control: Traditional detection methods are costly, with high consumable expenses.

Solution: Swabs can be regularly cleaned and reused, reducing long-term usage costs.

The surface cleanliness tester has become an essential tool in modern hygiene monitoring due to its speed, accuracy, and convenience. It not only addresses multiple pain points of traditional detection methods but also provides more efficient solutions for hygiene quality management across various industries. As the demand for hygiene and safety continues to grow, the surface cleanliness tester will play an increasingly important role in food safety, industrial production, and other fields.

Article address:https://www.molecularbio.cn/news/42.html