Microbial contamination has always been the 'Damocles sword' hanging over our heads in the fields of food safety, water quality monitoring, pharmaceutical production, and public health. Although traditional microbial detection methods, such as the culture dish method, are classic and reliable, they have pain points such as cumbersome processes, long time consumption (usually 24-72 hours or more), high professional requirements for personnel, and difficulty in responding quickly on site, which result in serious lag in risk prevention and control. Especially in foodborne disease outbreaks or water pollution incidents, every hour of delay can cause significant health damage and economic losses.

In depth analysis of industry pain points:

Timeliness crisis: 'Time is safety' is an iron law in the field of microbiological testing. The lag of traditional methods may result in contaminated products entering the market.

Complexity constraints: Sample preprocessing (grinding, dilution, filtration, enrichment, etc.) involves multiple steps, is labor-intensive, and can easily introduce errors or cross contamination.

Human and space dependence: requires a professional laboratory environment and skilled technicians, making it difficult to meet the immediate needs of the site, production line, or resource scarce areas.

Quantitative accuracy and flux bottleneck: Traditional methods are difficult to quantify and have limited flux, making it difficult to meet high-throughput screening needs.

Information island: Subjective interpretation of results and difficulty in real-time electronic tracking and management of data.

The way to break through: RVL microbial detection system - the wisdom of simplifying complexity

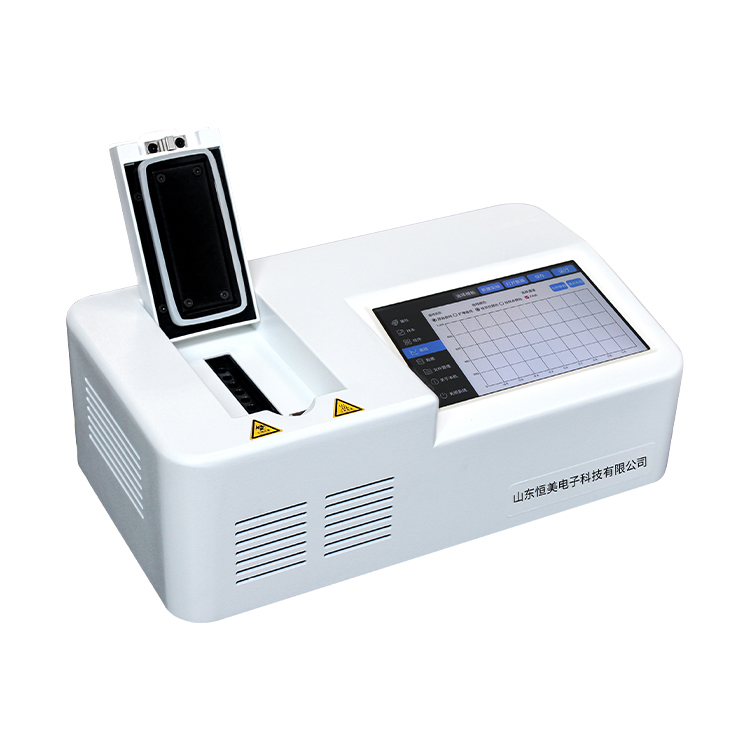

The RVL system creatively integrates miniaturized laboratories into an intelligent detection vial (RVL Microbial Detection Vial), combined with portable intelligent detectors, completely disrupting the detection process.

Core principle: A "bottle laboratory" that integrates multiple technologies

The RVL detection bottle is not a simple container, but a reaction and sensing platform that integrates multiple cutting-edge technologies:

Intelligent sensing core: The bottle integrates high-sensitivity biosensors to continuously monitor microbial metabolic activities (such as acid production, gas production, specific enzyme activity) or markers (fluorescence, electrochemical signals).

Targeted recognition technology: Based on different detection targets (such as Escherichia coli O157, Salmonella, Listeria, etc.), specific primers, antibodies, or enzyme substrates are pre-set to achieve high specificity recognition (theoretical specificity up to 99.999%).

Precise environmental control: The detector precisely controls the temperature and incubation time inside the bottle, creating optimal conditions for the growth or reaction of specific microorganisms.

Real time dynamic monitoring: The instrument continuously reads the sensor signals inside the bottle and converts the signal strength into the number of microorganisms (CFU) in real time through proprietary algorithms, achieving 100% quantitative analysis.

Disruptive technological advantages:

Zero pre-processing revolution: Solid, liquid, paste, and surface swab samples can be directly put into the detection bottle without any preprocessing - truly achieving "what you see is what you measure". Save time and eliminate pre-processing errors.

Fast response: The detection speed is 2-5 times faster than traditional methods. Clear results can be obtained within a few hours at the fastest (much lower than traditional 24-72 hours), winning golden time for quick decision-making.

Extreme sensitivity and specificity: Theoretically, one target microorganism can be detected with a specificity of up to 99.999%, greatly reducing the risk of false negatives and false positives.

Accurate quantification and high-throughput: Real time output of CFU values to meet strict quality control requirements. A single instrument can detect 8 samples in parallel at the same temperature, doubling the efficiency.

Extremely simple: "three-step operation" (sample addition, instrument insertion, and result reading), no professional microbiological background required, ordinary personnel can get started with simple training. The portable design extends the laboratory to fields, production lines, and restaurant kitchens.

Intelligent Interconnection: Directly connect to a computer, automatically generate professional testing reports, and achieve data traceability and management.

Safe and convenient: After use, it can be disposed of as expired drugs without any special hazardous waste disposal burden.

Comprehensive coverage: One bottle is versatile, covering the total number of live bacteria, coliforms/Escherichia coli (including O157 pathogenic strains), Enterobacteriaceae, Staphylococcus aureus, Pseudomonas aeruginosa, Salmonella, Listeria monocytogenes, Enterococcus, yeast and other core pathogenic bacteria and hygiene indicator bacteria.

Wide range of application areas and solutions:

The RVL system provides a fast and accurate end-to-end solution for microbial risk prevention and control in various industries

Food Safety (HACCP):

Pain points: Delayed microbiological monitoring of raw materials, process products, and finished products, resulting in high recall costs.

Solution: Quickly screen for pathogenic bacteria (such as Salmonella and Listeria) and hygiene indicator bacteria (such as Escherichia coli and Staphylococcus aureus) near the production line. Instant hygiene assessment of ingredients, tableware, and contact surfaces in cafes/restaurants. Case: Salmonella screening of raw milk in a dairy factory, traditional method takes 2 days, RVL takes 8 hours to produce results, intercepting a batch of contaminated raw materials to avoid large-scale production stoppage.

Water quality safety:

Pain points: Long monitoring cycles for microbial indicators in water sources, end-point water in pipelines, and treated water, resulting in delayed risk detection.

Solution: Water treatment plants, distribution companies, and regulatory agencies should conduct on-site rapid testing of total bacterial colonies, coliforms/Escherichia coli, and Pseudomonas aeruginosa. Case: A city's pipeline network is suspected to be contaminated, and RVL multi-point rapid detection has identified the section of the pipeline with excessive E. coli, completing emergency response within 2 hours.

Medicines and cosmetics:

Pain point: The sterile/microbiological limit test takes a long time and affects the release speed; Rapid feedback is required for production environment monitoring.

Solution: Rapid qualitative and quantitative analysis of raw materials, purified water, intermediate products, and environmental monitoring (surface, air settling bacteria). Case: Monitoring of Staphylococcus aureus on the surface of a clean area in a pharmaceutical factory, using RVL instead of traditional cultivation methods. The results were reported on the same day, accelerating environmental correction.

Centers for Disease Control and Inspection (CDC&CIQ):

Pain point: The outbreak of the epidemic requires rapid tracing; The speed requirements for customs clearance at ports are high.

Solution: Quickly screen for foodborne pathogens and waterborne pathogens on site, providing a basis for epidemic response and rapid customs clearance.

Environment and Public Health:

Pain points: Rapid assessment of microbial risks in public places (such as air conditioning systems) and post disaster environments.

Solution: On site testing of Legionella and Pseudomonas aeruginosa by consumer protection groups, business management agencies, and air conditioning maintenance companies. Case: A large shopping mall's air conditioning condensate water tested positive for Pseudomonas aeruginosa RVL, and the machine was immediately shut down for disinfection to avoid potential respiratory infection risks.

The culmination, leading the future

The RVL microbial detection system cleverly integrates the advantages of culture dish method (providing growth environment), enzyme method (specific substrate reaction), immune method (antigen antibody binding), and gene method (targeted nucleic acid recognition) into an intelligent detection bottle. It not only solves the fundamental pain points of traditional methods, but also redefines the possibilities of microbial detection with ultimate convenience, speed, precision, and intelligence.

In today's world where microbial risks are ubiquitous, the RVL system provides a powerful technological weapon to ensure the safety of the entire chain, from farm to table, from source to faucet, and from factory to home. It is not only an innovation in the laboratory, but also empowers every site and position that requires instant answers with professional level microbiological testing capabilities. Embracing RVL means embracing a more efficient, safe, and intelligent future for microbial control.

Article address:https://www.molecularbio.cn/news/30.html